Nesting lines of the series BAZ 890n IQ

Nesting lines with integrated software and application modules for:

- cabinet making / furniture fronts

- frame furniture / upholstery furniture

- caravan construction

- facade construction

Intuitive operation and highly efficient dust extraction ensure highest productivity.

Work tables

- BAZ 890n IQ 2,500 x 1,250 mm

- BAZ 891n IQ 3,000 x 1,600 mm

- BAZ 892n IQ 3,000 x 2,100 mm

- BAZ 895n IQ 4,000 x 2,100 mm

Automatic loading with integrated barcode labelling as well as intelligent workpiece removal ensure smooth operation.

Loading table

Automatic loading

- hydraulic lifting table with load capacity 3,000 kg

- lifts the workpiece stack sensor-controlled to the processing height

- when a workpiece is transferred to the processing machine, the lifting table automatically moves to the correct processing height

- recesses for loading with forklift

- BAZ 892n IQ and BAZ 895 IQ: double scissor lift table

- CNC-controlled beam with pneumatic alignment unit positions the uppermost workpiece with pin-point accuracy (only in conjunction with labelling)

Note:

- maximum stacking height 290 mm

- maximum stacking height when using a pit 1,000 mm

Pneumatic alignment unit

Option Labelling

Automatic labelling device

- error-free labelling

- high efficiency: nesting and labelling of the following workpiece takes place simultaneously

- identification of each workpiece supports the further production process

Barcode connection

- barcode scanner and barcode software

- supported barcodes: 1D barcode, 2D data matrix code

Label

- label contains the following information:

- workpiece dimensions, barcode, customer name, order number, information on edge processing, reference point for subsequent processing including all important information for production

- format can be adapted to customer requirements

- QR code can be used

Workpiece feeding

Loading station

- vacuum suction cups safely pick up and transport the workpiece to the work table

- a compact roller table transports the workpieces gently - thanks to low-friction rollers

Work table

- grid table for mounting the MDF softboard (panel dimensions 2,070 x 2,800 mm)

- grooves and chamfers in the grid table provide an optimized vacuum

- manual control of the vacuum range

- option: Activation/deactivation of the vacuum depending on the X position of the gantry

Side positioning device

- stop fence left and right for a trouble-free feeding of the workpieces

- side alignment cylinder for precise positioning of the infed panel

Drilling and routing

The high-quality Z slide with two separate CNC axes ensures optimum dust extraction, protects the ball screw and guarantees the best routing quality. The weight of the machining units is evenly distributed over two axes. This ensures stability and a higher machining quality.

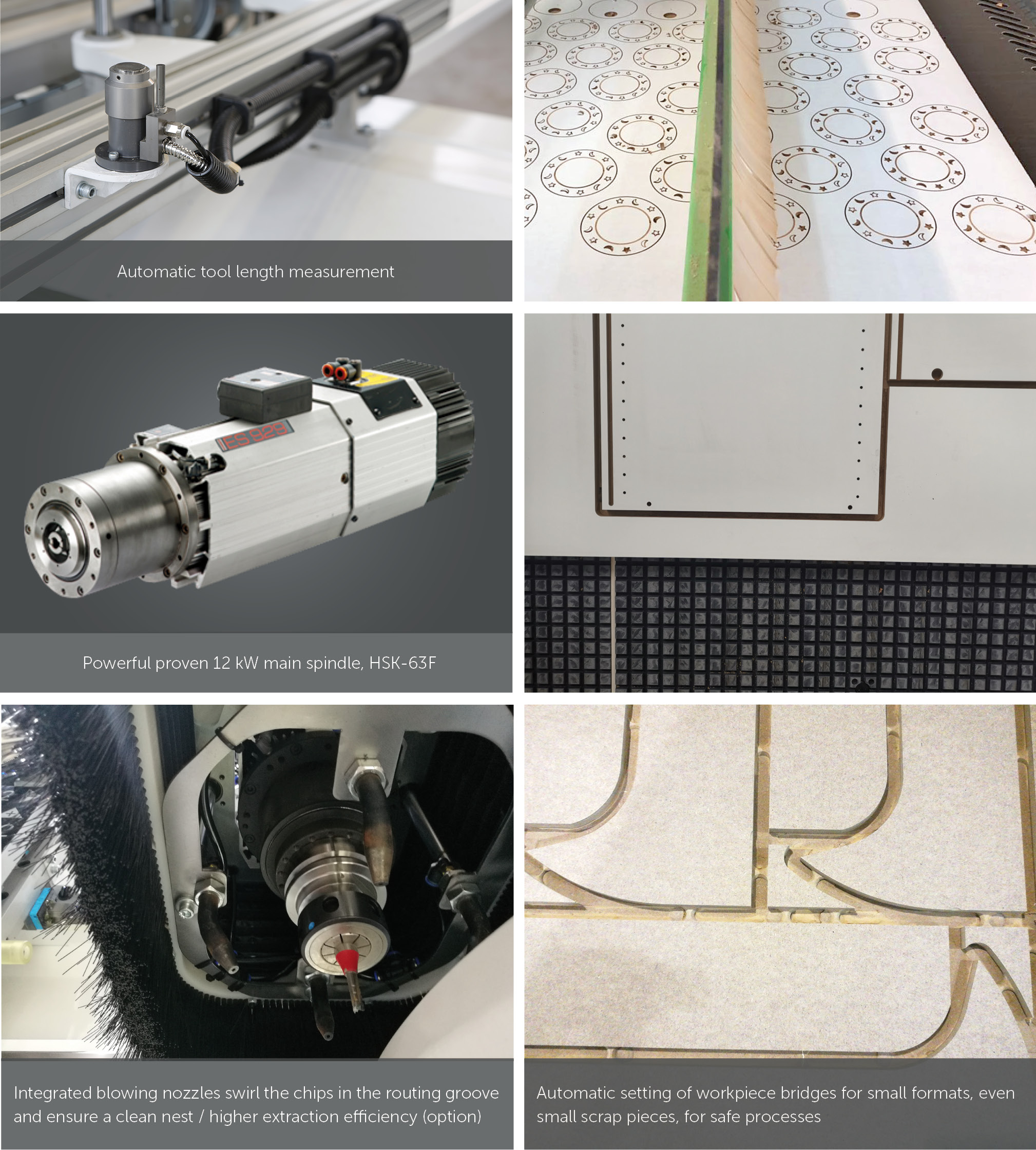

Main spindle

- power: 12 kW, 18,000/24,000 RPM

- tool interface: HSK-63F

- air cooling, highly precise, stable and durable

Drilling block

- 10 vertical drills, grid 32 mm

- drill shank diameter: 10 mm

- max. drill diameter: 35 mm

Servo driven tool changer with 8 positions

- HSK-63 F tool interface

- touch probe for tool length measurement

- digital AC servo motors - designed for mounting various equipment options

- empty space detection prevents a crash in case of incorrect operation

Tool sensor and tool holder

- tool sensor for an efficient tool setting

- tool change device allows easy tool change

- tool length is read after change and compared with the integrated tool database

Unload station and dust extraction

Automatic unloading station

- conveyor belt for conveying workpieces

- optoelectronic sensor ensures that workpieces do not fall down at the end of the belt

- 4 dust extraction points

Dust extraction

- four central extraction points for clean workpieces

- dust extraction at the work table when removing the workpiece and transporting it to the unloading table

- upper and lower dust extraction for efficient dust removal after the machined workpiece has left the worktable

- program controlled suction nozzles

Technical data

BAZ 890n IQ | BAZ 891n IQ | BAZ 892n IQ | BAZ 895n IQ | ||

Working range | X axis | 2,500 mm | 3,000 mm | 3,000 mm | 4,000 mm |

| Y axis | 1,250 mm | 1,600 mm | 2,100 mm | 2,100 mm | |

| max. workpiece thickness | max. 30 mm | ||||

Max. travel speeds | X axis | 50 m/min | |||

| Y axis | 50 m/min | ||||

| Z axis | 20 m/min | ||||

Main router spindle | amount | 1 | |||

| speed | 24,000 RPM | ||||

| power | 12 kW | ||||

| tool interface | HSK-63F | ||||

| collet | ER32 | ||||

Automatic tool changer | amount of tools | tool magazine with 8 positions | |||

| control | servo | ||||

Drilling block | vertical drills | 10 | |||

| max. drill diameter | 35 mm | ||||

| power | 1.7 kW | ||||

| speed | 4,000 RPM | ||||

Vacuum pump | power | 2 x 5.5 kW | 2 x 7.5 kW | ||

| suction flow rate | 2 x 160 m3/h | 2 x 250 m3/h | |||

| suction pressure | 0,8 kg/cm2 | ||||

| cooling | air cooled | ||||

Dust extraction | pipe diameter | 1 x 200 mm, 1 x 125 mm | |||

| dust extraction speed | min. 28 m/s | ||||

| extraction connection | Ø 250 mm, height 2.400 mm | ||||

| extraction capacity | min. 4.950 m3/h | ||||

| pressure loss | min. 2.200 Pa | ||||

| Note: Weight relief at extraction hose! | |||||

Compressed air | 7 bar | ||||

Power supply | power | 26 kW / 68A | 31.4 kW/68A | 35 kW/68A | |

| frequency | 50 Hz | ||||

| voltage | 400 V, 3 phases | ||||

Machine dimensions | length x width * | 10,000 x 3,500 mm | 12,850 x 4,500 mm | 12,850 x 5,000 mm | 15,850 x 5,000 mm |

| height | 2,600 mm | ||||

| weight | 6,000 kg | 7,600 kg | 8,160 kg | 9,000 kg | |

* Note: plus safety devices depending on local conditions