Horizontal Panel Saw NPL 3 HG

Machine frame

- robust machine frame to accommodate the saw carriage

- welded steel frame with heavy steel plates

- heat treated

Pressure beam

- same pressure on the whole surface of the panel during processing

- piano type dust cover provides a completely enclosed blade guard and prevents flying dust and chips

- hand protector: protective device mounted on pressure beam for protecting operators

- main operation interface with emergency stop button

Air floating tables

- with steel balls reduces any scratches on panel surface and ensures smooth panel transmission

- pressure fan under working table reduces compressed air losses 2 x 2.2 kW=4.4 kW

Rear feeding

- maximum stack height up to 1200 mm

- heavy duty rear feeding hydraulic lifting table

- max. load 5 t

Side alignment

- to compress panel tightly during cutting

- coordinated with grippers for high cutting accuracy especially for narrow panels

- chain transmission

- rubber covered contact rollers fix the panel in their position

Feeding

- central location of servo motor for allocating average power on each side of actuating device

- to guarantee high precision and stability

- motor 1.5 kW

- rack and pinion

Clamping device

- servo driven rack and pinion mechanism for high feeding precision

- magnetic railing ruler measuring system (high precision, no contact, no abrasion, with no need to adjust, no influence of dust)

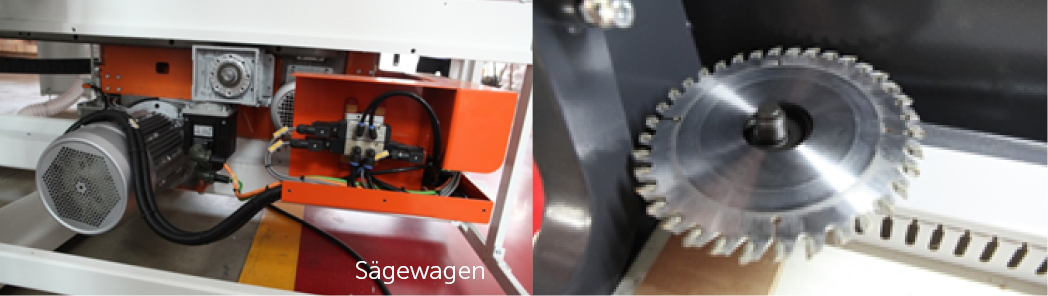

Saw carriage

- standardized assembly for high precision

- height of main saw automatically adjusted by the sensor according to panel thickness

- guided with round guide rail on top and bottom

- 22 mm solid plate

- unilateral suspension structure for stable movement of saw carriage

- servo motor driven through rack and pinion to ensure the cutting precision

- positioning speed 5-100 m/min freely programmable

- height adjustment of main saw and scoring saw guided by linear sliding block

- main saw blade: Ø 460 x φ 60

- scoring saw blade: Ø 180 x φ 45

- main saw (18 kW) and scoring saw (1.5 kW) independently controlled

Automatic lubrication system

- ensures smooth operation

- easy maintenance, reduces maintenance and repair efforts

Control

- user-friendly HMI coordinated with USB interface

- network card

- mouse and keyboard

- controlled by IPC

- Windows operating system and optimizing software

- cutting pattern is generated automatically

- label printing function available

Optimizing software

- connected perfectly with saw for best layout of material list

- function for rest material management

- rest material will be utilized first

- optimizing the outturn

- panel texture and panel store are optional according to the material list

- OptiCut Software (OPTION)

Operational software

- layout, direction and total number of panels can be indicated graphically in the screen while cutting

- position of rest material is optional

- use of panel guidance and cutting type can be determined

- software confirms amount of panels during pattern input

- then works out the cutting lines and label dimensions, if needed

- automatically switching to next pattern as soon as one pattern finished

Technical data

| NPL 330 HG | NPL 380 HG | ||

| Cutting | Max. cutting length | 3,300 mm | 3,800 mm |

| Max. cutting height | 120 mm | ||

| Saw blade projection (above workpiece support) | 130 mm | ||

| Lift table width | 2,500 mm | ||

| Max. stacking height without pit | 1,200 mm | ||

| Max. stacking weight | 5,000 kg | ||

| Main saw | Motor | 18 kW | |

| Outer diameter saw blade | 460 mm | ||

| Inner diameter saw blade | 60 mm | ||

| Speed | 3,910 RPM | ||

| Vorritzsäge | Motor | 2,2 kW | |

| Outer diameter saw blade | 180 mm | ||

| Inner diameter saw blade | 45 mm | ||

| Speed | 4,150 RPM | ||

| Saw carriag | Feed rate | 8-50 m/min | |

| Backward speed | 120 m/min | ||

| Motor | 1.5 kW (AC servo motor) electronically controlled • steplessly adjustable | ||

| Angle pressing device | NC controlled • up to 120 mm | ||

| Air cushion table | 1 x 1,900 x 620 mm 2 x 1,690 x 620 mm Option: 3 x 1,900 x 620 mm | 4 x 1,900 x 620 mm | |

| Working heigth | 960 mm | ||

| Power | Total power consumption | 40 kW | |

| Pneumatics | min. 6 bar | ||

| Weight | 10,500 kg | 13,500 kg | |

| Layout | 9,585 x 9,200 x 2,020 mm | 9,585 x 9,200 x 2,020 mm | |