FKS 320 IQ

The sliding table

The sliding table - the heart of the sliding table saw

Precision, smooth running and long term reliability. These are the preconditions for economic success with your sliding table saw.

All operations start with a precise rip cut. The table of the FKS 3 IQ series slides smoothly and precisely – the guides are hardened round bars which carry the sliding table - a robust, proven design for constant satisfaction when operating the FKS 3 IQ series saws of Lohmeyer. Of course, the system is maintenance-free.

Quality and security

As a professional you know that the sliding table system guarantees the accuracy of the cross cuts, because the sliding table accomodates the cross cut fence.

If you are smart, you leave nothing on chance, but go for quality, precision and an engineering which secures constant satisfaction when operating the Lohmeyer FKS 3 IQ series sliding table saws.

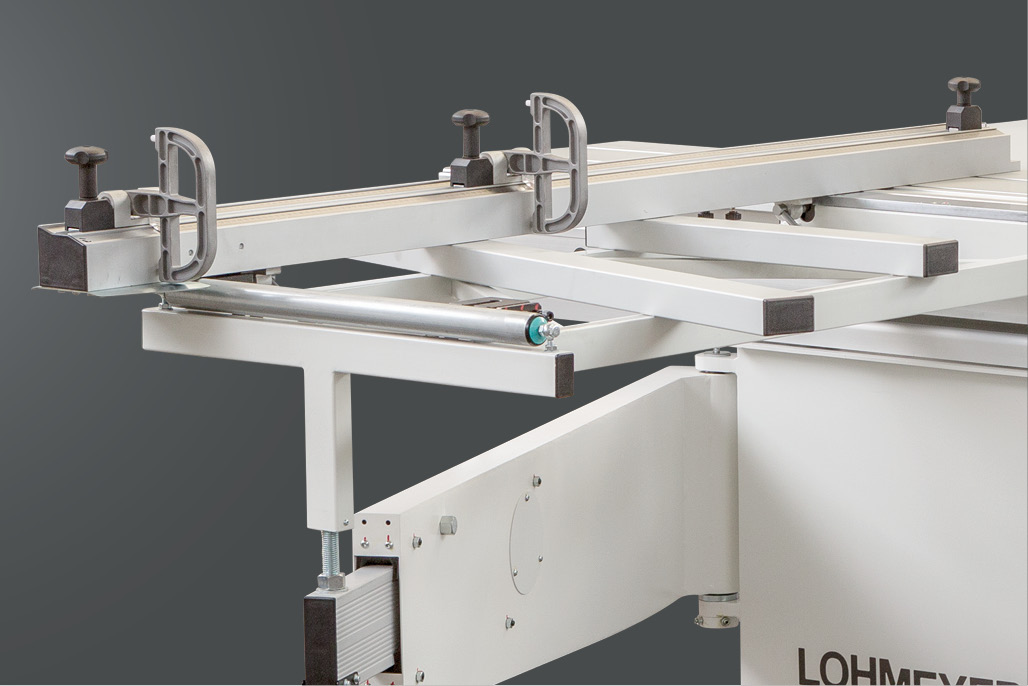

The cutting size

Cutting length of the sliding table

Table length FKS 320 IQ: 3,200 mm

This corresponds to the following cutting lengths:

3,100 mm with scoring saw

3,200 mm without scoring saw

Cutting width of the rip fence

Max. cutting width FKS 320 IQ = 1,200 mm

Cutting length of the cross cut fence

1,900 mm to be read at the lower scale,

3,200 mm with telescopic device, to be read at the upper scale

A roller at the end of the cross cut fence supports the loading and unloading of instable workpieces.

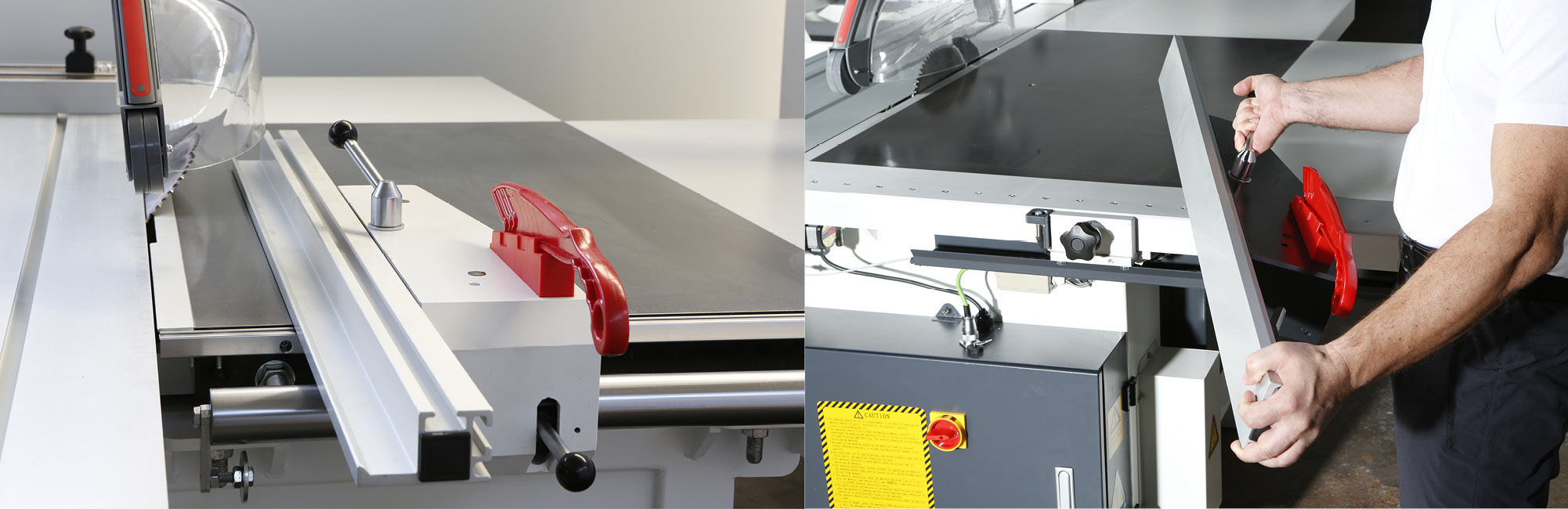

The rip fence

Easy to adjust

Move the fence easily. The hardened and polished round bar makes it possible.

Tilting

Your workpieces are sometimes slightly larger? No problem. Simply rotate the fence just below the machine table level.

Flipping

Narrow parts are cut easier and safer with a tilted ruler. After flipping it is only 10 mm high. When tilting the saw blade, there is enough space available.

Positioning

Precise positioning by means of an integrated scale in the machine table

Adjustable length

When workpieces of the same dimensions are cut from one panel – just pull the fence ruler back behind the saw blade and use the cross cut table. This is convenient, precise and will save a lot of time.

The cross cut fence

The double roller carriage accomodates the cross slide. A precise factory set up guarantees high accuracy of parallelism to the saw blade for many years.

Inclined scales make it easy to read the measurement. The gap-free folding units are easy to move. The fence ruler is removable and can be positioned at the front or back side of the cross table.

The precise cross fence can be easily removed. Even without tools.

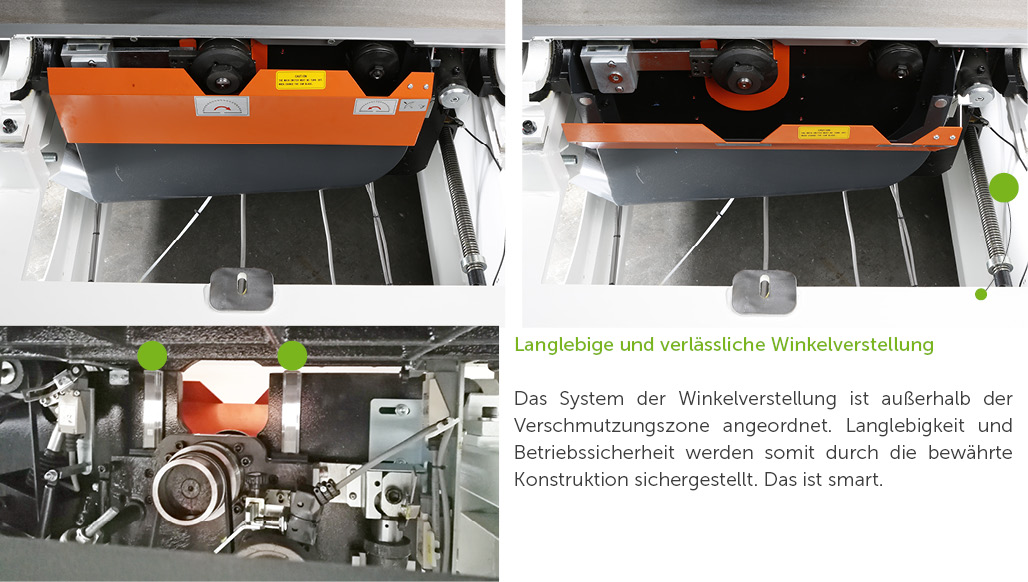

The saw aggregate

Besides the slide table, the saw aggregate is another main element of the sliding table saw.

The design of the Lohmeyer sliding table saw guarantees a high degree of operational reliability and smooth running. This means for you: daily availability and exactly the precision you need for your customers in everyday woodworking.

Durable and reliable height adjustment

Dust-protected linear guides ensure durable and precise height adjustment.

Clean and safe working thanks to protective hood

A transparent and ergonomically designed protective hood for cuts with 90° saw blade and a separate protective hood for angular cuts ensure safety and reduce the operator‘s exposure to dust and chips by directly extracting the dust at the source of origin.

Durable and reliable angle adjustment

The angle adjustment system is located outside the contamination zone. Durability and operational reliability are thus ensured by the proven design. That is smart.

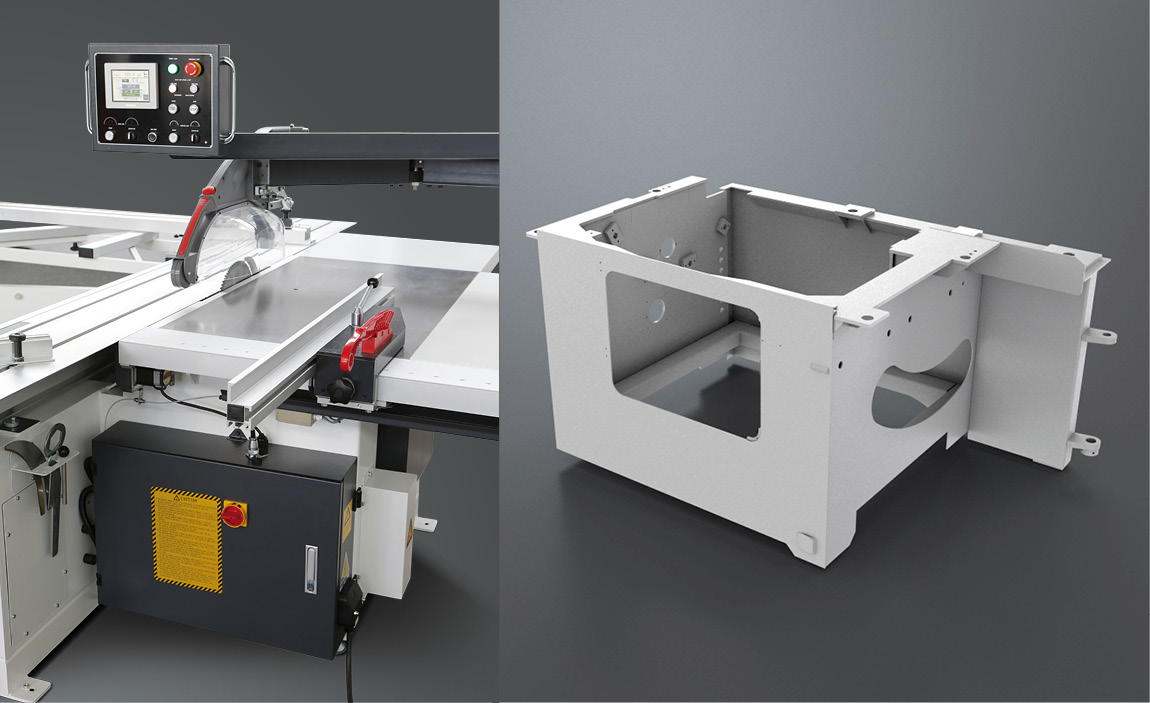

The base frame

A solid basis is the foundation of success. This is particularly true for the core components the sliding table and the saw aggregate. Both units need a solid foundation - the base frame.

Manufactured with high-tech laser cutting machines it is a closed design and very rigid. This guarantees the smooth running and stability of the FKS 3 IQ series.

The mitre fence

Single sided mitre fence

The mitre fence enables the operator to cut narrow and wide pieces precisely. It is easy to adjust and mounted on the sliding table without tools in a few simple steps. The cross cut fence table can be put underneath the mitre fence to support longer and thinner workpieces.

The adjustable handle at the sliding table permits ergonomic and user-friendly operation.

Double sided mitre fence

The compact design and the light weight of only 12 kg is convincing right away. The registered design of the splitting wedge makes it easy to cut off market pieces and reduces chip outs. Due to the included wall mounting unit the double sided mitre fence may be positioned at the wall.

Safe repeatability

A scale with its magnifier support the length and angle positioning. The length of the scale is 1,375 mm. The gap free stop system allows repeatability. For often used angles (5°, 10°, 15°, 22.5°, 30°, 45°, 50°, 60°, 67.5°) a length compensation is available.

Exact display variants

The length and angle position is adjusted through the scale and the digital readout. The accuracy of the digital readout is 0.01°, for length positioning 0.1 mm. Four angles including the specific length compensation can be memorized.

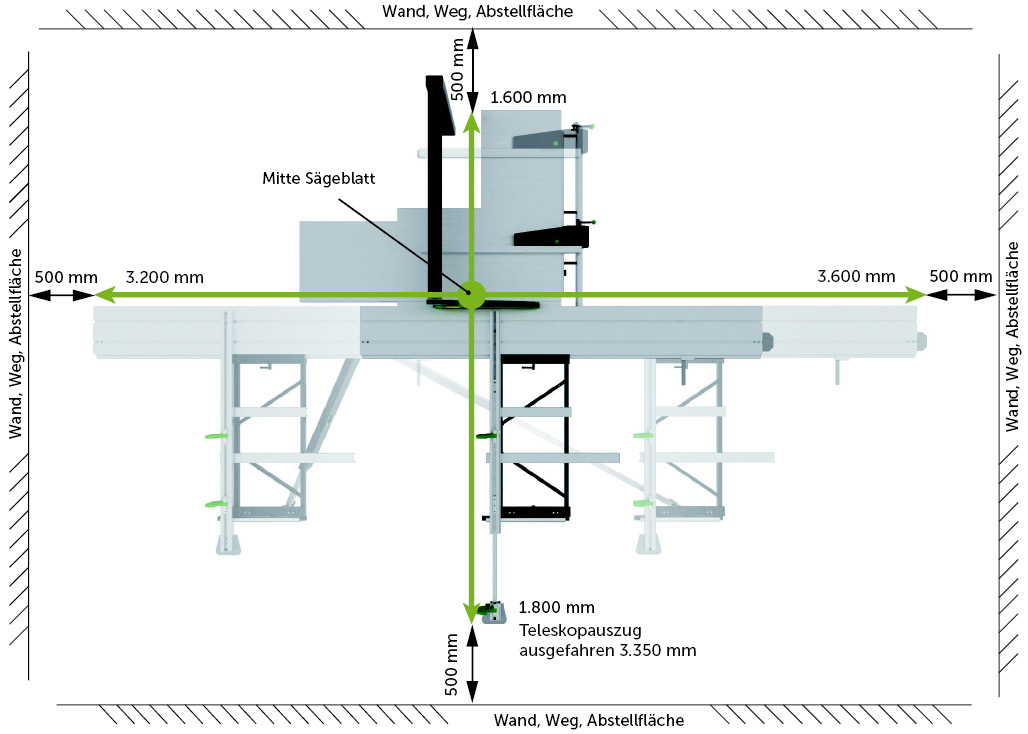

The space requirement

The space requirement for the machine including the traverse of the sliding table is approx. 6,800 mm x 3,400 mm for both FKS 320 IQ and FKS 355 IQ.

For placing and removing bulky workpieces enough free space between the machine and adjoining equipment or buildings needs to be considered. Further room is to be provided for depositing workpieces and residual pieces.

Specification of FKS 320 IQ

Compare the performance data of individual FKS models in a direct tabular overview: