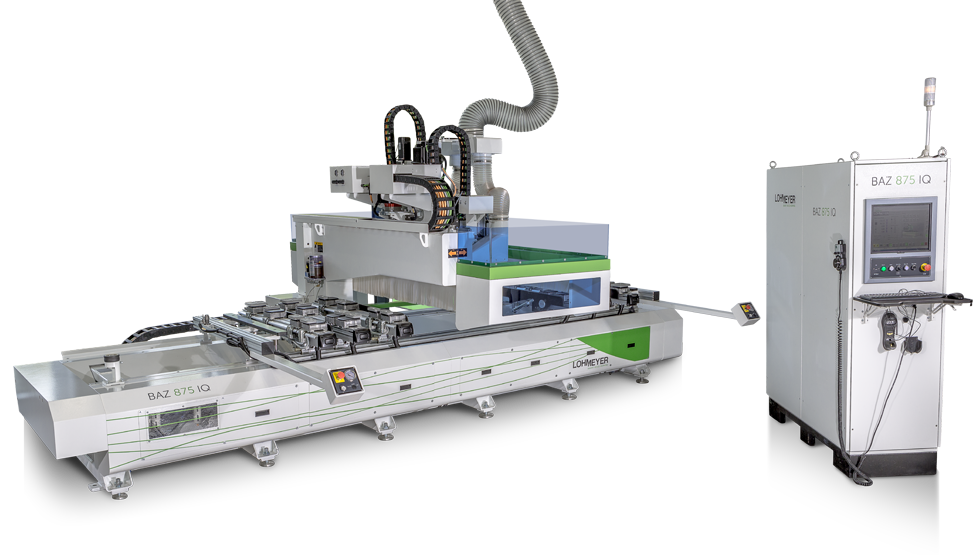

CNC Machining Center BAZ 875 IQ

Standard equipment

- powerful 12 kW HSK 63F tool change spindle

- tool changer with 8 positions driven by servo motor

- 14 vertical spindles, horizontal spindles 2+2 in X/Y, grooving saw in X

- 6 servo drives: X / Y / 2 x Z / C axis and tool changer

- chip conveyor belt

- barcode reader

- replaceable suction system

- clearly arranged switch cabinet with air conditioning system

- workshop-oriented DDX programming software with CAM module

- central lubrication

Configuration of the work table

Work table

- 6 aluminum benches (4 benches with panel lifting device, 1,250 mm long)

- hold down device for narrow pieces (optional)

- LED positioning system (optional)

Stop system with electronic stop sensor

- panel lifting device for easy workpiece positioning

- 6 rear stops, moveable with support

- 6 stops front/centre, moveable with support

- 2 side stops

Chip conveyor belt

- integrated in the frame

- for the removal of chips and residues out of the machine frame

Suction cups

- flexible suction system with LED indication (optional)

- 50 mm height:

10 suction cups - 125 x 140 mm

8 suction cups - 125 x 75 mm

6 suction cups - 125 x 50 mm

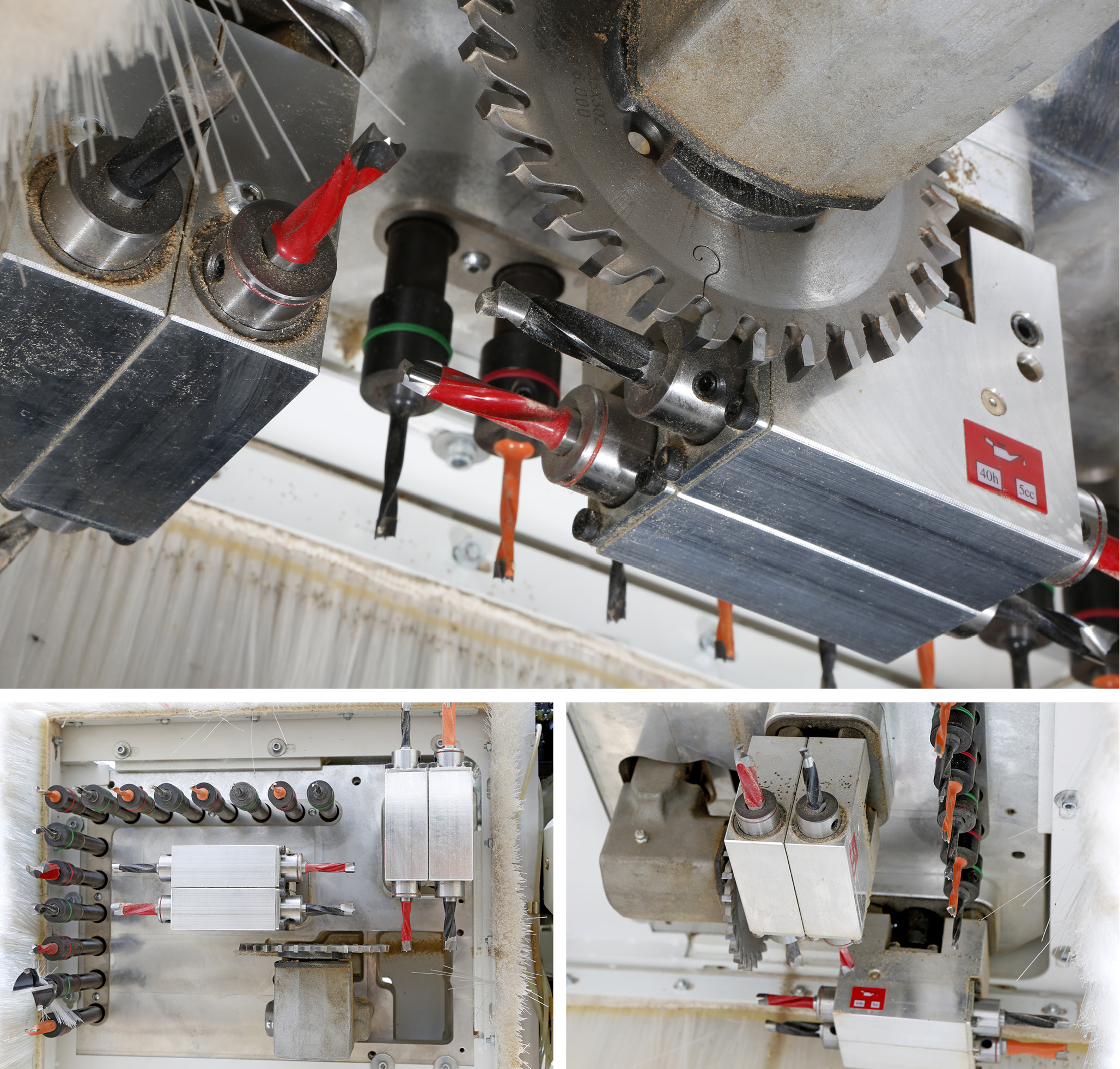

Servo driven tool changer with 8 positions

- HSK 63 F tool interface

- powerful 12 kW spindle, 18,000/24,000 RPM

- empty space detection prevents a crash in case of incorrect operation

- touch probe for tool length measurement

- digital AC servo motors

- dust-protected

Drilling block configuration

- 14 individually selectable vertical spindles

(8 in X axis / 6 in Y axis, 32 mm grid) - 8 horizontal drilling spindles Ø 8 mm

2 + 2 in X direction

2 + 2 in Y direction - integrated grooving saw 1.7 kW, 4,000 RPM

(inner Ø saw blade 35 mm, max. Ø 120 x 5.5 mm)

Technical data

BAZ 875 IQ | ||

Working range routing spindle | X axis | 3,000 mm |

| Y axis | 1,250 mm | |

| max. workpiece thickness | 80 mm (depending on tool setup length) | |

Working range drilling block | X axis | 3,000 mm |

| Y axis | X row 1,500 mm, Y row max. 1,690 mm | |

| max. workpiece thickness | 80 mm | |

Work table | 6 moveable benches with 4 suction cups each | |

Max. travel speeds | X axis | 80 m/min |

| Y axis | 80 m/min | |

| Z axis | 20 m/min | |

Main router spindle | amount | 1 |

| speed | 24,000 RPM | |

| power | 12 kW | |

| tool interface | HSK-63F | |

| tool changer | 8 positions | |

Drilling block | vertical drills | 14 (8 in X, 6 in Y) |

| horizontal drills | 8 (2 + 2 in X, 2 + 2 in Y) | |

| grooving saw | integrated grooving saw in X (120 mm diameter) | |

| power | 1.7 kW | |

| speed | 4,000 RPM | |

Vacuum pump | power | 5.5 kW |

| suction flow rate | 140 m³/h | |

| suction pressure | 0.8 kg/cm² | |

Compressed air | required air pressure | 7 bar |

Dust extraction | pipe diameter | 200 mm |

| dust extraction speed | min. 28 m/s | |

| extraction connection | Ø 250 mm, height 2,400 mm | |

| extraction capacity | min. 4,950 m3/h | |

| pressure loss | min. 2,200 Pa | |

| Note: Weight relief at extraction hose! | ||

Power supply | power | 26 kW / 68A |

| frequency | 50 Hz | |

| voltage | 400 V, 3 phases | |

Machine dimensions | length x width * | 7,100 x 3,700 mm |

| height | 2,200 mm | |

| weight | 4,800 kg |

* Note: plus safety devices depending on local conditions